Product Description

A & M Manufacturing Co.Ltd. specializes in the production of cast iron parts, including grey cast iron, ductile iron, malleable cast iron, alloy cast iron, nickel resist, high chromium cast iron, austempered ductile iron. It adopts resin sand casting process or shell casting process and has the experience of producing iron castings. It is widely used in automobile industry, railway parts, pump valves, municipal construction, pipeline systems, engineering machinery, hydraulic systems, etc. on.

Our main cast iron castings include fire hydrant fittings, cast iron valves, cast iron pumps, cast iron fittings, submersible pump fittings, cast iron casings > cast iron casings, auto fittings, agricultural machinery fittings, construction machinery fittings and more.

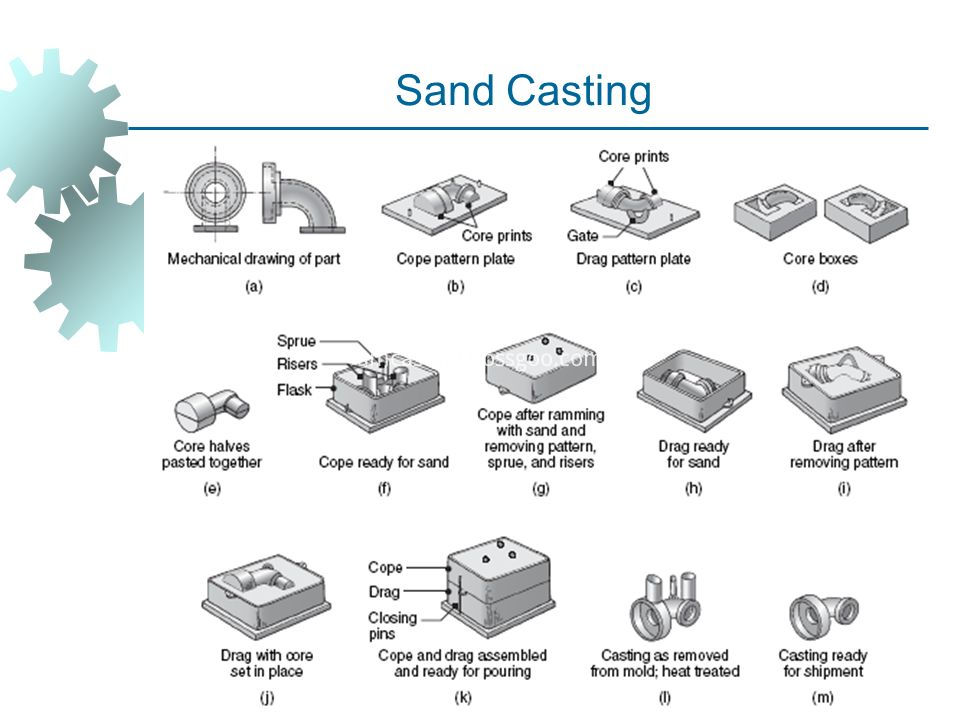

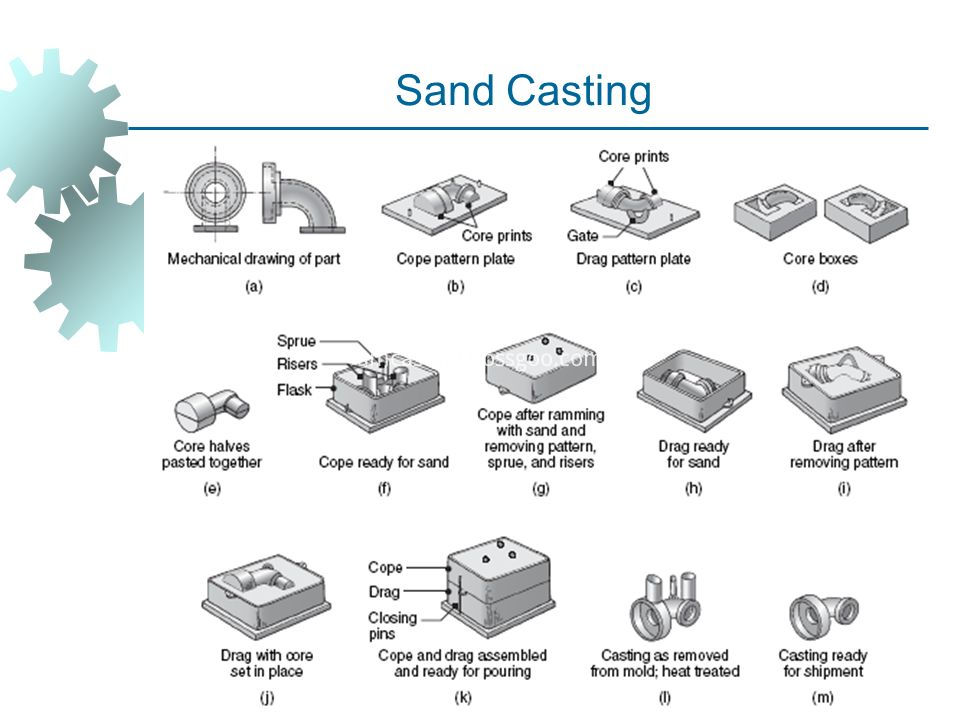

Sand casting, also known as sand molded casting, is a metal casting process characterized by using sand as Sand casting, The term "sand casting" can also refer to an object produced via the sand casting process. Sand castings are produced in specialized factories called foundries. Over 70% of all metal castings are produced via a sand casting process.

Sand casting is relatively cheap and sufficiently refractory even for steel foundry use. In addition to the sand, a suitable bonding agent (usually clay) is mixed or occurs with the sand. The mixture is moistened, typically with water, but sometimes with other substances, to develop strength and plasticity of the clay and to make the aggregate suitable for molding. The sand is typically contained in a system of frames or mold boxes known as a flask. The mold cavities and gate system are created by compacting the sand around models, or patterns, or carved directly into the sand.

Basic process.

There are six steps in this process:

1.Place a pattern in sand to create a mold.

2.Incorporate the pattern and sand in a gating system.

3.Remove the pattern.

4.Fill the mold cavity with molten metal.

5.Allow the metal to cool.

6.Break away the sand mold and remove the casting.

.png) Contact Now

Contact Now