Product Description

The spare parts of engineering machinery/mining machinery manufactured mainly include:major planet carrier,bracket,axis round,

brake hub,box,connector,differential mechanism,poly grid casting,and all kinds of cast iron and cast steel products,producing all

kinds of heavy industry,forklift,excavator,loading machine and other industrial fields.

sand casting, also known as sand molded casting, is a metal casting process characterized by using sand as Sand casting, The term

"sand casting" can also refer to an object produced via the sand casting process. Sand castings are produced in specialized factories

called foundries. Over 70% of all metal castings are produced via a sand casting process.

Sand casting is relatively cheap and

sufficiently refractory even for steel foundry use. In addition to the sand, a

suitable bonding

agent (usually clay) is mixed or occurs with the sand. The

mixture is moistened, typically with water, but sometimes with other

substances, to develop strength and plasticity of the clay and to make the

aggregate suitable for molding. The sand is typically

contained in a system of

frames or mold boxes known as a flask. The mold cavities and gate system are

created by compacting

the sand around models, or patterns, or carved directly

into the sand.

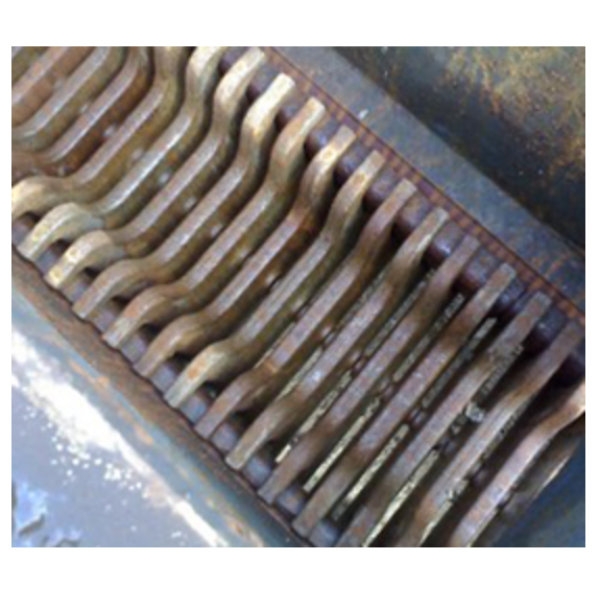

Grate plate of Engineering Machinery

Liner plate of crusher parts

Hammer crusher parts

Mining machinery parts

Crusher parts

Basic process

There are six steps in this process:

1.Place a pattern in sand to create a mold.

2.Incorporate the pattern and sand in a gating

system.

3.Remove the pattern.

4.Fill the mold cavity with molten metal.

5.Allow the metal to cool.

6.Break away the sand mold and remove the

casting.

.png) Contact Now

Contact Now