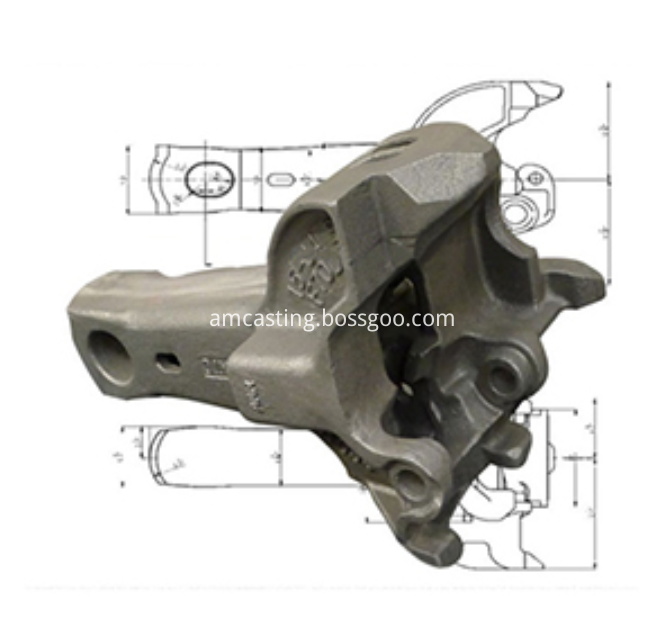

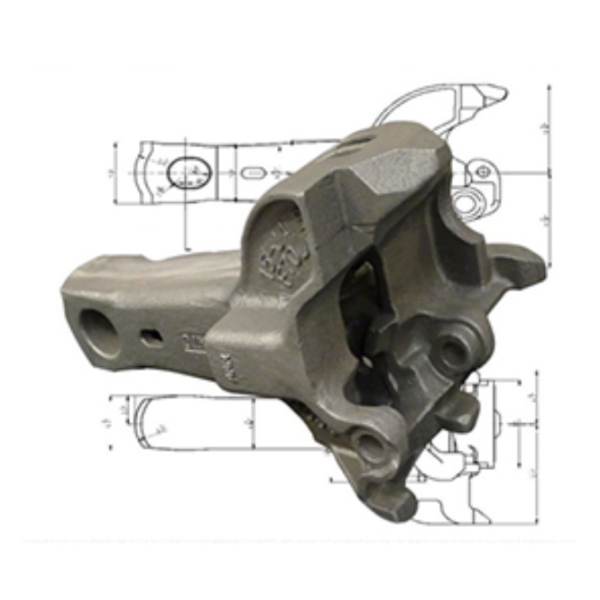

Product Description

Material of wagon coupler: 20ГЛ, E Grade steel

Weight of railway hook: from 180kg to 250kg

DESCRIPTION

high quality AAR Railway coupler, wagon coupler, railway hook

We can produce all types of coupler according to client's drawing or standard ,ex:CA-3 SA-3 ,13#,17# etc.

The strength of railway coupler meets the requirements of the AAR M-203,Steel Specification.

Process:robot automatic core making and setting production line, using resin hardening sodium silicate-bonded sand for modeling, whole-core core making and refining outside the furnace technology, we can realize whole-core robot automatic core making and setting production.

Sand Casting, also known as sand molded casting, is a metal casting process characterized by using sand as Sand casting, The term "sand casting" can also refer to an object produced via the sand casting process. Sand castings are produced in specialized factories called foundries. Over 70% of all metal castings are produced via a sand casting process.

Sand casting is relatively cheap and sufficiently refractory even for steel foundry use. In addition to the sand, a suitable bonding agent (usually clay) is mixed or occurs with the sand. The mixture is moistened, typically with water, but sometimes with other substances, to develop strength and plasticity of the clay and to make the aggregate suitable for molding. The sand is typically contained in a system of frames or mold boxes known as a flask. The mold cavities and gate system are created by compacting the sand around models, or patterns, or carved directly into the sand.

Also we have the enough experience of producing Austempered Ductile Iron Casting, austenitic nodular iron.

There are diverse ways to describe the Ductile Iron Castings, such as – Ductile Iron, Ductile Cast Iron, SG, SG Iron, Spheroidal Graphite and Spheroidal Graphite Cast Iron etc., all of them can be used and interchangeable.

.png) Contact Now

Contact Now