Product Description

As a leading lost-wax casting factory in China with over ten years exporting experience, We can provide the premium quality casting products with you on base of reasonable price.

OEM parts according to customers' requirements: sample or dwg

1) Process available: silicon jell and water glass

2) Material available: stainless steel, alloy steel, carbon steel

3) Weight: 0.01-100kg

4) Surface treatments: sand blasted then painted, electrophoresis, zinc plated, polishing...

5) Heat treatments: tempered or annealed

6) Machining: CNC and NC machining, turning, milling, drilling, boring, threading, grinding machines and test facility.

Detail informations:

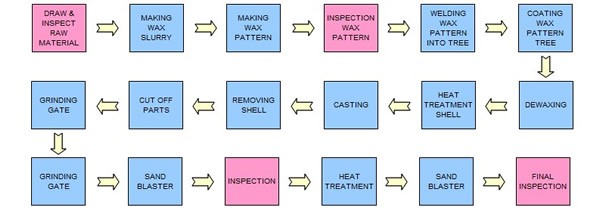

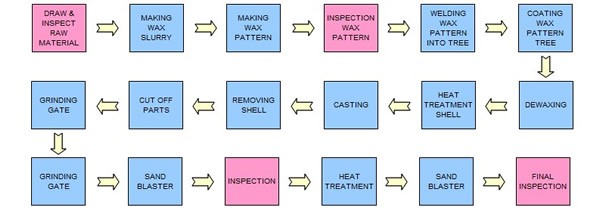

1.technology process:silica sol or soluble glass investment casting

2.Various material:stainless steel,duplex steel,aluminum alloy,copper alloy,ductile iron.

3.standards:ASTM,JIS,BS,DIN,EN,ISO

4.capacity:1000tons/year

5.Application: Automotive & Transportation Parts; Fitness Equipment; Mining Machinery; General Industrial Equipment; Home Appliance; architectural parts etc.

6.Extremely intricate parts are castable

7. perfect equipments

our advantage

1.A&M takes the advanced silicasol precision investment casting process, can produce all kinds of ultra-thin, high precision , special specifications and complicated shape of high temperature alloy, aluminum alloy, stainless steel casting parts

2.A&M use various raw material,include AISI SS316L,316,304,8630,4340,4140,17-4PH,DIN1.4581 and 1.4408,JISSCS13,SCS14,aluminum alloy,copper,iron..so on

3.A&M owns the advanced management mode and domestic advanced precision casting technology, ensure product accuracy can reach to CT3~CT6, surface roughness lower 1.6μM, advanced technology make the products without the inner defects such as porosity, slag inclusion, shrinkage, organize uniform density.

4.all products could reach or exceed the national standards

5.our firm produce standard or non standard casting parts,comply with ASTM, AISI, DIN, BS and JIS,also according to customers' special requirements or sheet to do it.

6.the products we owned refer to multiple industries,consist of mining,construction machinery,pipe,valve,marine,train,auto and electrical.

.png) Contact Now

Contact Now