The items Lower and Upper Arms, were previously manufactured as a forging and are used in Batch Centrifugals { Sugar Industry.}

A&M mainly products is steel and iron casting.These products are widely used in auto, railway, mining machine, engineering machine, steel mills,lifting machine,valve and pumps etc. Investment casting product is one of our advantage product.

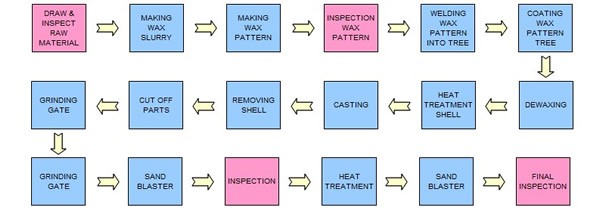

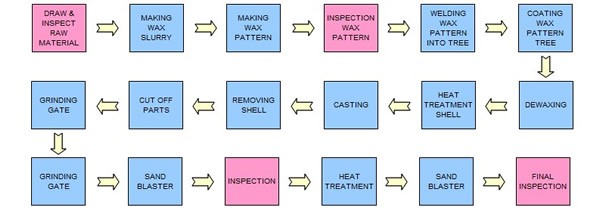

Steel casting is our most important products. Taiyuan SIMIS Precision Casting Inc. has the enough experience to produce steel castings. It has three professional branch plants producing stainless steel casting. One plant uses lost wax casting process to produce normal steel casting, such as astenitiuc stainless steel ( CF8, CF8M, CF3 and CF3M), Martensitic stainless steel ( 1Cr13, 2Cr13); precipitation-hardening stainless steel( 17-4PH). The second investment casting factory uses vacuum furnace to do superalloy castings, such as turbine, turbine blade, supercharger, Ni-base alloy casting, Cr-base alloy casting. The third casting factory uses resin sand casting process to produce stainless steel sand casting. Also we have enough and advanced CNC machining equipments, such as CNC vertical machining center, CNC turning machines, CNC milling machines. It can produce many types of steel parts from 0.005kg to 2000kg. These steel casting parts produced by us are mainly used in automobile industry, construction, ship, medical equipment, pipe line, petrochemical industry and so on.

A&M factory with casting workshop and machining workshop, we can provide final products to customers. Most casting factory in China without machine workshop, it means your final products may be casted in factory A, and then machining in factory B.

.png) Contact Now

Contact Now