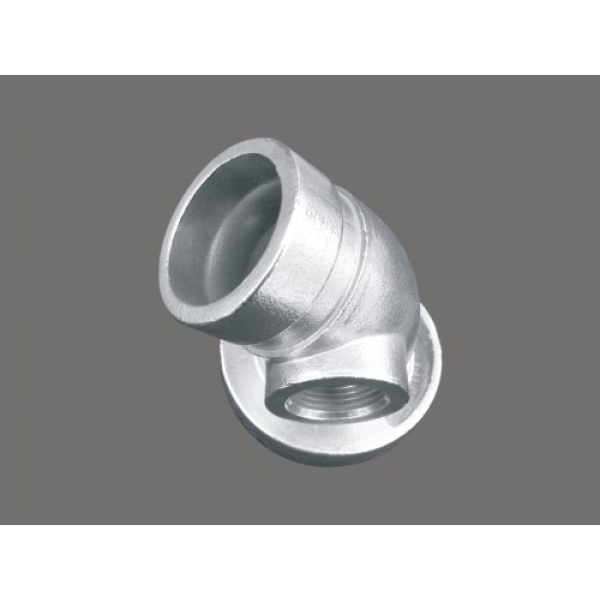

Product Description

Lost Wax Casting is the main

technology of investment castings. In most conditions, it can be regarded as

investment casting.

The main process of

lost wax castings is: mould design--mould making--wax injection--tree

assembly--shell making-dewax-shell roasting-pouring-cleaning-heat

treatment-machining-package.

Advantages of lost

wax castings:

a, Accuracy:

dimension tolerance--CT5~CT7,roughness--Ra2.5~6.3μm,weights range from 10g to

80kg;

b,Surface shape

and inner cavity is almost not limited, we could manufacture lost wax castings

with minimum wall thickness 0.5mm;

c, Almost all

kinds of material can be used, such as steel, aluminum, copper, superalloy and

so on.

Disadvantage of

lost wax castings:

The production

cycle is relatively long and it is not suitable for large products in terms of

the features of this kind of process.

Classification of

lost wax casting:

1. Sodium silicate

casting: large surface roughness, low dimension accuracy with short shell

making cycle. The hardening technique is chemical process. Normally most of

Carbon Steel Investment Casting and alloy Steel investment casting are made by

this kind of lost wax casting process.

2. Silica sol

casting: Small roughness, high dimension accuracy with high material costs and

long shell making time. The hardening process of shell is a natural process

under certain temperature and humidity. Normally stainless steel investment

castings are made by this kind of lost wax casting process.

As a leading

manufacturer of lost wax castings, A&M has the experience to produce almost

all types of lost wax castings. Most of our lost wax castings are widely used

in automotive, aerospace, marine, medical equipment, power plants and other

industries.

Very similar to the '

Investment Casting ' but particularly suited to larger castings giving a far

superior surface finish and dimensional precision to a ' Sand Casting.

.png) Contact Now

Contact Now